High Speed 32cavities 28mm 30mm 38mm Plastic Mineral Water Bottle Lids Closure High Quality Cap Compression Machine

Description

Basic Info.

| Model NO. | US-24 |

| Clamping Way | Hydraulic & Mechanical |

| Automation | Automatic |

| Computerized | Non-Computerized |

| Certification | CE, ISO9001:2008 |

| Color | Customers′ Request |

| Machine Weight | Different |

| Screw Diameter | 32mm-180mm |

| Clamping Force (Kn) | 2300 Kn |

| Material Application | PP PE PS ABS etc |

| Electrical Equipment | World Famous Brand |

| Injection Pressure | 150MPa--250MPa |

| Transport Package | Waterproof Membrane Cover and Wooden Box |

| Specification | 36 Cavities |

| Trademark | US-36 |

| Origin | China |

| HS Code | 8477590000 |

| Production Capacity | 10000 |

Product Description

Product DescriptionFully Automatic 36 Cavity 28mm 30mm Neck 500ml Bottled Mineral Water Caps Plastic PE Bottle Lids Injection Compression Molding Machine Price

Our automatic plastic perform and cap injection molding machine adopts a thermal flow system and high-pressure injection molding to get high precision of bottle mouth, bottleneck and screw. It can inject all kinds of plastic parts such as bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, pomponents for automotive, household, eletronics, telecommunication, etc.

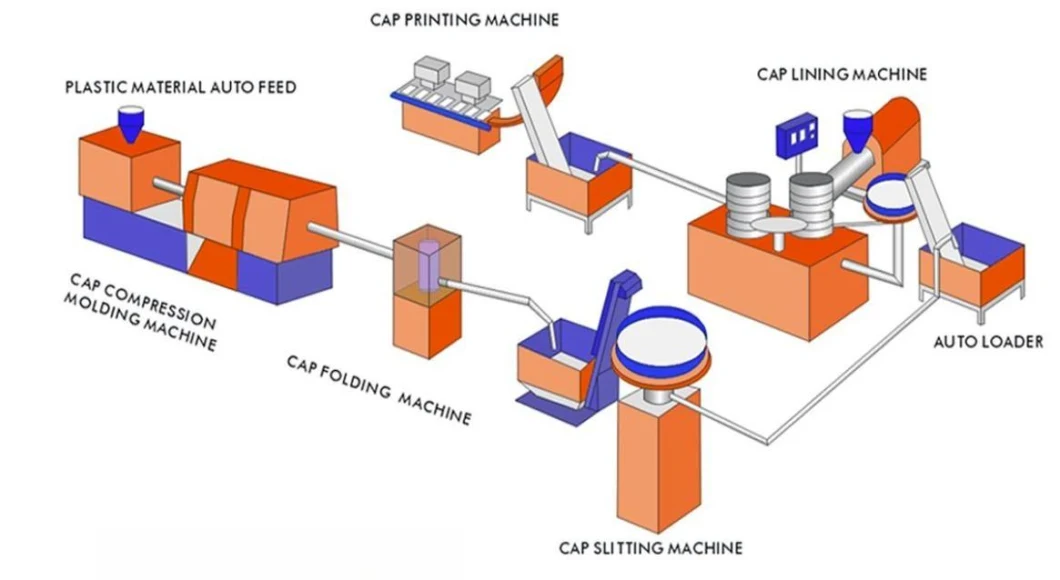

Working principle

In a short word,Ushine cap compression molding machine works as simple process: A precisely measured drop of resin, cut from acontinuous extruded stream, is placed into a transfer wheel. The same wheel also takes finished caps out of the main wheel.Position 1: The transfer wheel comes to a position above on empty cavity of the main wheel and drops the plastic into it.Position 2: The cavity lifts vertically up into the core and the actual molding takes place.Position 3: The plastic now spreads between core and cavity, climbing up the cap side walls under relatively low pressure. Ittherefore leaves no sprue point, which bring a great advantage for the caps whose surface need decorating.

Position 4: The fully formed cap is now cooling.Position 5: The cavity moves down leaving the cap on the core. The core parts will have continuous actions to separate the capamper brand from the bush, and separate the cap's thread parts (the main cap body) from inner core. Finally, with the help of lowpressure compressed air, the cap will separate from the core part completely.

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3.We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6.24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7.12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9.Good after-sale service offered, please get back to us if you got any questions.

Suzhou Ushine Material Technology CO.,Ltd. is a professional and dynamic company of beverage filling machine. Our company is located in Suzhou City , Jiangsu Prov. China . It is 100kilomiters far away from Shanghai . Adhering to the spirit of "technology as pilot, face the world,excellent quality, first class ever" and the purpose of "scientific management, exploitation and innovation, sincere and pragmatic, service-oriented", the company forms the talent team in reasonable structure and adopts advanced technology to develop and supply the good products and service.

Prev: 16 Cavities Self

Next: Multi Cavity Mineral Water Bottle Hot Runner Valve Gate Pet Preform Mould

Our Contact